Call(WhatsApp Us)

+8618988990383Email Us

postmaster@laeyolabs.com广州市花都区花山镇华辉路18号

微观化妆品创意产业园E栋整栋

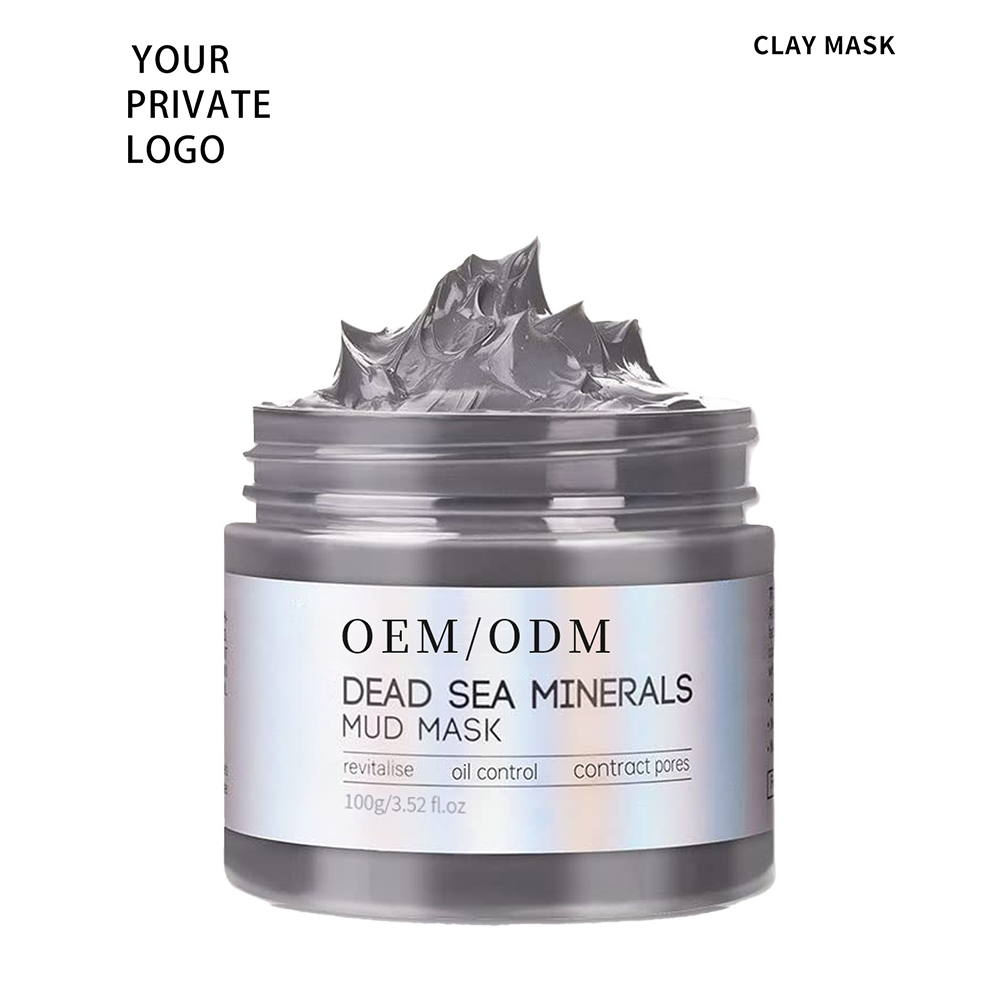

Deep-cleansing mineral-rich mud mask derived from Dead Sea sediments, designed for intensive detox and complexion revival.

From fast sampling to iterative optimization—aligned to your market and positioning.

Stable production workflow with quality checkpoints for consistency and scale-up.

Packaging options, decoration, labeling/INCI coordination—helping you launch shelf-ready SKUs.

all skin types, dull skin, oily skin, congested pores, tired complexion

deep cleansing, detoxifying pores, mineral nourishment, revitalizing skin, improving texture

Adults seeking spa-grade skin detoxification or mineral-based skincare care solutions.

Ensures consistent product performance during shelf life.

Conducted as needed to verify cleansing and detox results.

Routine microbial safety checks before shipment.

For UK skincare OEM/ODM, audit QA checkpoints starting with raw material inspection against COAs to ensure purity and regulatory alignment. During manufacturing, monitor in-process controls: check viscosity every batch to prevent separation, maintain pH within 5.5-7.0 for skin compatibility, and verify pigment dispersion for consistency. Filling audits should focus on temperature windows (e.g., serums at 20-25°C to preserve actives), fill weight accuracy (±1%), and prevention of air bubbles that cause leakage in transit. Packaging checks include cap torque variance (10-15 Ncm for pumps) and label adhesion in humid UK conditions to avoid bubbling. Final product testing must cover microbial limits, stability studies at 25°C/60% RH, and challenge tests for preservation efficacy. MOQ drivers: batch sizes of 5,000-10,000 units optimize filling lines and cost. Sampling timeline: 3-4 weeks for lab samples, 8 weeks for pilot batches with packaging fit checks. Lead time from production to shipping is 10-12 weeks, including compliance docs like CPSR, GMP certificates, and UK Responsible Person details. We support all testing and documentation for smooth market entry.

The most common reasons skincare products fail UK stability tests include **formulation incompatibility**, **packaging integrity issues**, and **non-compliance with testing standards**. Formulation failures often stem from ingredient interactions affecting pH or viscosity over time, while packaging leaks can occur due to poor seal designs or material reactions. Testing shortcomings may involve incorrect storage conditions or insufficient test duration, leading to unreliable shelf-life claims. To prevent failures, we conduct **feasibility studies during sampling**, which take 4-6 weeks and include small-batch stability checks under UK-simulated conditions. **MOQ guidance**: For effective testing, we recommend a minimum of 5,000 units per SKU to cover sample costs and repeated cycles. **Packaging validation** is critical; we test pumps and bottles for leakage risks under temperature swings, common in UK shipping. We assist by providing **detailed documentation**, such as stability reports and safety assessments aligned with UK regulations. **Lead time impact**: If tests fail, production can delay by 2-3 months for reformulation. Our R&D team offers reformulation support to ensure products meet claims without compromising quality, backed by audit-ready test records.

The section contains no information, so I cannot detail the distinctions between fragrance-free and unscented for UK skincare labels or recommend safest wording. Typically, for UK markets, labeling must align with EU-derived regulations, where 'fragrance-free' implies no added fragrance ingredients, and 'unscented' may involve masking agents. Without data, I cannot confirm specifics. In OEM/ODM skincare, clear claims are crucial for formulation and testing. MOQ often starts at 3000-5000 units per SKU, with sampling taking 2-4 weeks after formula approval. Packaging must be reviewed for label accuracy, and we support stability testing and documentation for compliance, but final regulatory approval is the brand's responsibility. Lead time from production to shipping is usually 6-8 weeks, depending on order size and testing. Always verify with current UK standards to avoid non-compliance risks.

As an OEM/ODM skincare manufacturer, we prevent label issues in UK bathrooms and logistics by selecting appropriate materials and processes. We recommend synthetic paper or vinyl labels with waterproof adhesives that withstand high humidity, and UV-cured or thermal-transfer inks resistant to moisture and friction. Factory testing includes ASTM D2247 humidity chamber tests and transit simulation with ISTA standards to mimic UK shipping vibrations and temperature changes. For new clients, MOQ starts at 10,000 units per SKU to justify custom label tooling and ensure cost efficiency. Sampling typically takes 3-4 weeks after approval, including pilot runs to verify label adhesion and ink durability under controlled humidity cycles. We integrate label checks into production QA, such as visual inspections for bubbling and rub tests after 24-hour humidity exposure at 40°C/90% RH. Packaging solutions like shrink-wrapping or carton inserts protect labels during logistics, and we support documentation like UKCA/CE compliance reports and material safety data sheets (MSDS) for customs. Lead time from production to shipping is 6-8 weeks, including microbial hold-time and final audit, but can vary based on label complexity and order volume.

In the UK, fragrance allergen labeling for skincare is regulated under the UK Cosmetics Regulations, which mirror EU requirements. You must list all 26 designated allergens in the ingredient list if they exceed thresholds: 0.001% for rinse-off products like cleansers, and 0.01% for leave-on products like creams. This is critical for UK market access and avoids recalls. For OEM/ODM projects, MOQs typically start at 5,000-10,000 units to offset costs of GC-MS testing, which analyzes fragrance oils for allergen concentrations. Sampling timelines add 2-4 weeks for formulation tweaks and label design iterations. We provide test reports and supplier declarations to document compliance. Packaging must include allergen lists clearly on labels; we check for proper formatting and language. Lead times from sampling to production may extend by 1-2 weeks for compliance checks. We assist with documentation but cannot guarantee regulatory approval, as it depends on final product details.

For a premium finish on UK skincare, the material and adhesive must work together. We recommend clear BOPP or white PP films as the primary facestock. These are waterproof, resistant to oils and lotions, and provide an excellent, durable printing surface that prevents ink migration into the product. For adhesives, permanent acrylic-based options are standard; they bond strongly to glass, PET, and PP, withstand refrigeration cycles, and do not ooze or leave residue. MOQ for custom-printed labels typically starts around 10,000-15,000 units per design, depending on size. Sampling lead time for label approval is 10-15 working days after artwork is finalized. Critical UK compliance points include correct UKCA or UKNI marking (if applicable), full ingredient listing in English, net quantity (e.g., 30 ml), and manufacturer/importer details. We will support you with document review and batch-specific Certificates of Conformance. A common failure point is label bubbling or peeling on curved containers like dropper bottles in high humidity. Our control is to conduct real-condition adhesion tests on your specific packaging before bulk production. We also advise against paper labels for products that will be used in bathrooms, as they degrade quickly.

For skincare bottles, we recommend using premium PE or PP labels with UV-cured inks and protective matte/gloss varnishes that resist abrasion. Our MOQ starts at 5,000 units per SKU, allowing for proper material testing. During sampling (2-3 weeks), we conduct rub tests using ASTM D5264 and simulate shipping conditions with temperature/humidity cycling. For US compliance, we provide material safety data sheets and can support FDA registration documentation. Final production includes 100% visual inspection for label adhesion, with lead times of 6-8 weeks from approved samples.

For skincare contract manufacturing, audit incoming raw material certificates of analysis (CoA) for active ingredients and preservatives. In-process, verify pH stability at 30-minute intervals during mixing and pump torque variance testing for packaging compatibility. Finished goods require microbial testing (challenge tests, total count), stability testing at 25°C/60% RH, and packaging integrity checks. Our MOQ starts at 5,000 units per SKU with 4-week sampling timeline. We provide full documentation including ISO 22716 and GMP compliance reports. Lead time is 8-12 weeks post-approval, with 3-day hold-time checks for microbial validation before shipping.